Rebuild Perioperative Processes for Better Efficiency

By James Hanson, MD

Director (retired), Moss Adams

By Kim Pittenger, MD

Director, Lean Health Care Practice, Moss Adams

Original Publish Date: January 13, 2021

As your health care organization reintroduces more elective procedures following the initial emergency response to COVID-19, there’s a unique opportunity to shift previous perioperative processes to more dynamic strategies that could enhance how you use vital resources from the outset.

Every resource counts, with operating room costs hovering around $35 per minute—sometimes even above $100—depending on the surgery and location and not including surgeon and anesthesiologist fees.

Below we outline how organizing perioperative work into focus areas for improvement through lean methodologies can help reduce waste and add value, as well as enhance utilization, reduce unit costs, and boost patient trust thanks to on-time starts and excellent outcomes.

5 Perioperative Focus Areas

Plan to analyze perioperative areas or steps in care with focus on their inter-relatedness—including how they do or don’t set each other up for smooth flow without delays or defects.

Especially in the wake of the pandemic, this includes aligning leadership of all perioperative areas and setting goals for improvements in the flow of information, people, and equipment to improve patient safety and costs.

Significant progress can be made to achieve numerous improvements—including:

- Reduced set-up times, delays, and inventory costs

- Higher patient satisfaction and staff engagement

- Enhanced safety

- Improved revenue cycle efficiency

Lean methodologies achieve these improvements by mapping the patient’s journey and unleashing your team’s creativity for problem solving in a system of continuous improvements through daily management, leader standard work, visible metrics, goals for all team members, daily accountability, and mistake-proofing.

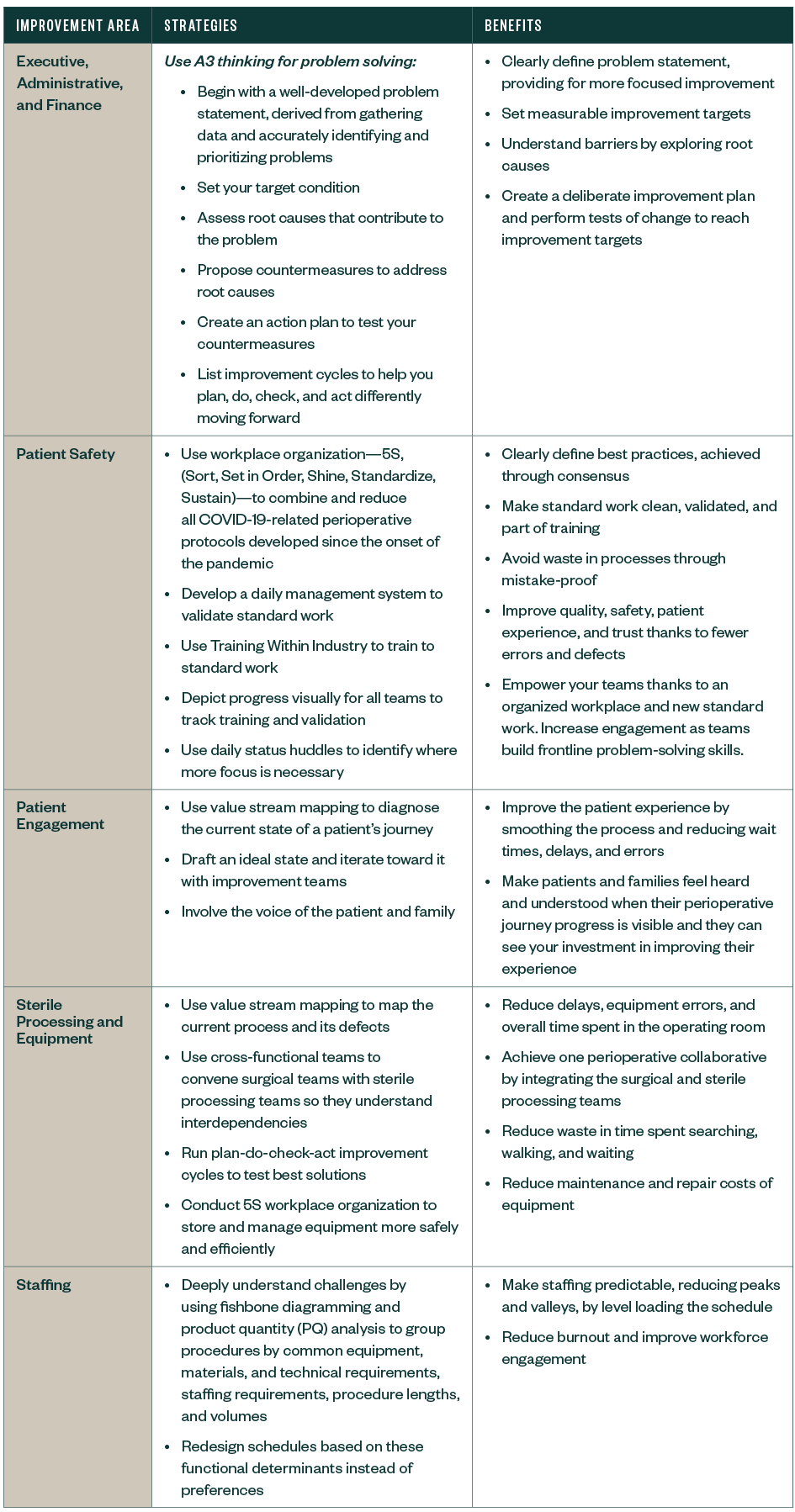

Here are some focused strategies and benefits across five categories.

In Tandem Strategies

Goals for 3 Key Perioperative Phases

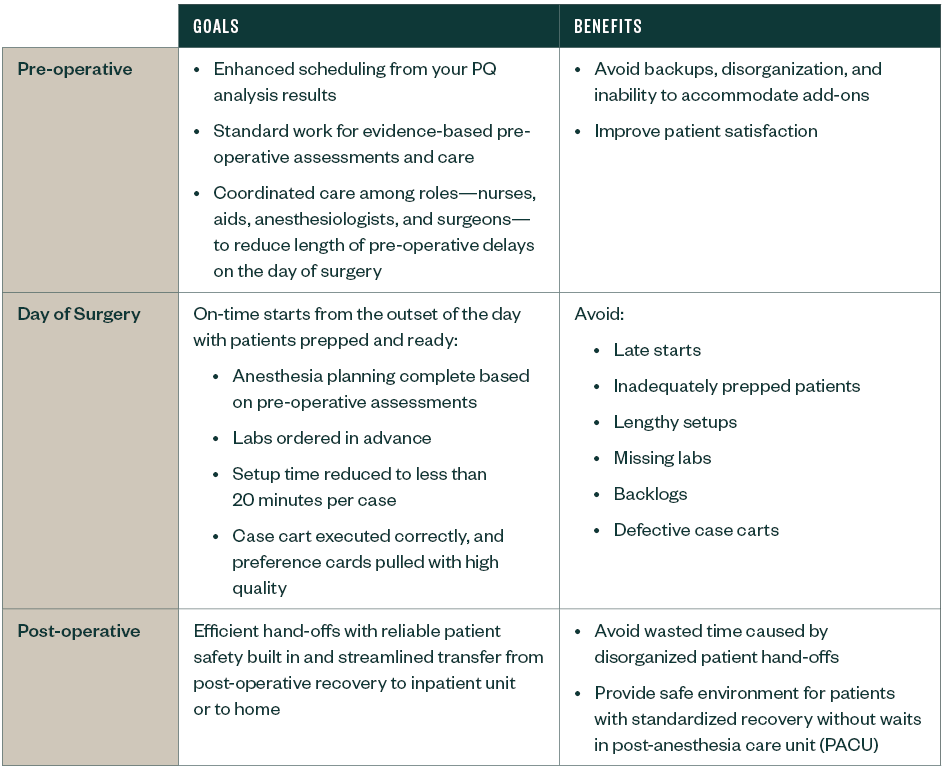

Your organization may set goals at each phase within the perioperative value stream:

- Pre-operative

- Day of surgery

- Post-operative

At each phase, focus should always be on the needs of surgeons and patients.

By using lean methodologies, the goal is to prevent delays, improper equipment preparation, disorganized patient hand-offs, and more.

Build Quality into Each Step of the Process

We’re Here to Help

To learn more about how your organization can rebuild perioperative processes for better efficiency, contact your Moss Adams professional.

James Hanson retired in 2020 after more than 30 years in the health care industry. He’s a physician executive who specializes in quality and performance improvement, medical staff affairs, clinical education, electronic records implementation, and medical group operations.

Kim Pittenger is a director at Moss Adams. He began his career in family medicine in 1979. By 2004, he became a strong believer in the Toyota Production System and its ability to improve the ease of delivering quality care and contribute to financial success. Kim left private practice after nearly 40 years to devote his career to medical care innovations inspired by lean methodology. He can be reached at (206) 302-6430 or kim.pittenger@mossadams.com.

Assurance, tax, and consulting offered through Moss Adams LLP. Investment advisory services offered through Moss Adams Wealth Advisors LLC.